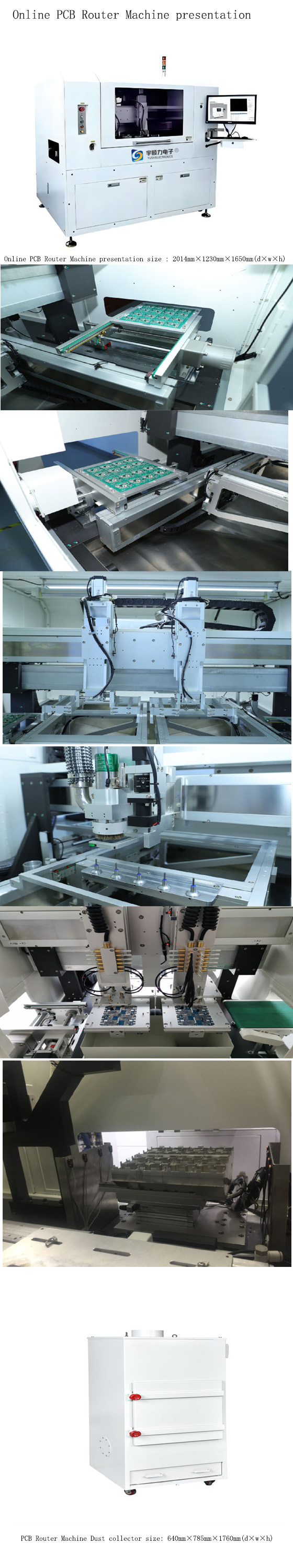

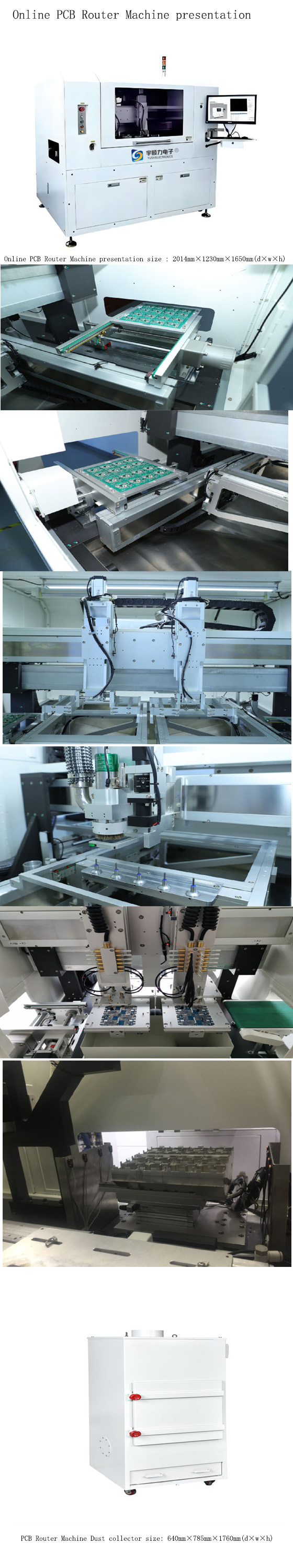

YUSH YS-880 series automatic visual online PCB Depaneling

Router

- 2 -

Product Description

:

YS-880 series automatic visual online PCB Depaneling Router

1. The PCB Depaneling replaces manual breaking, V-CUT or

PUSH cutting defects, effectively improving product quality and

reducing external stress on the product.

2. Equipped with high-pixel CCD lens, auxiliary program

teaching and editing functions, higher precision and more

precise.

3. Automatic MARK point positioning correction system,

real-time display of moving path and simulated route tracking,

effectively improving cutting accuracy.

4. The program left and right workbench copy, block copy,

display, multi-angle connection board copy, single-step tracking

modification function, block edit modification function,

accurately simplify the time of program production and improve

editing efficiency.

5. The vacuum cleaner and high-voltage static elimination

device made of high-power imported fan improve the dust collection

effect.

6. Tool life monitoring to extend the life of milling

cutters.

7. Adopt dual platform to cut PCB board, reduce waiting time

and effectively increase production capacity.

- 3 -

Product Features:

YS-880 automatic visual online PCB Depaneling Router

The whole series is equipped with high-speed CCD vision automatic

correction system, which greatly improves the cutting accuracy

and operation efficiency. Adopt high-speed spindle to separate

the board, with low cutting stress and high precision, suitable

for PCB boards with irregular shapes. Dual working platforms can

perform cutting and circuit board placement at the same time,

improving work efficiency. Self-developed dust collection device,

low noise, high efficiency, easy maintenance and cleaning.

Application industry:

YS-880 automatic visual online PCB Depaneling Router

YS-880 automatic PCB Depaneling machine is equipped with visual

alignment correction function as standard, which is more suitable

for high-precision and high-capacity PCB cutting and splitting

operations. Such as mobile phones, automotive electronics,

medical equipment, aerospace. Widened and large size is suitable

for the sub-board processing of large circuit boards such as

digital TVs, PC motherboards, servers, etc. Standard jigs or

special jigs can be used to assist in cutting the board to increase

productivity. Use dual working platforms to place workpieces to

reduce waiting time and increase productivity.

- 4 -

Technical parameters and specifications:

YS-880 automatic visual online PCB Depaneling Router

1.Cutting parameters

|

Cutting accuracy

|

± 0.1mm

|

|

Repeatability

|

± 0.02mm

|

|

Maximum moving speed

|

XY axis 1000mm/s, Z axis 800mm/s

|

|

Cutting speed

|

0-100mm/s

|

|

Maximum working range

|

300mm*350mm

|

|

PCB cutting thickness

|

0.3-6mm

|

|

Applicable cutter size

|

0.8-3.0mm

|

|

Feeding method

|

Rail conveyor

|

|

Discharge method

|

Rail conveyor

|

|

Flow direction

|

Left→right or right→left

|

2.Image

|

Mark point all types

|

Standard shape

|

|

Round

|

|

Square

|

3.Function

|

Cutting function

|

Straight line, semi-circular

arc, circular arc

|

- 5 -

|

Copy left and right

|

|

Rotating copy

|

|

Matrix copy

|

Automatic correction

compensation

|

4.Control parameters

|

XYZ control method

|

CNC Dedicated controller

|

|

Maximum speed of spindle motor

|

60000/min

|

|

Vacuum method

|

Up suction/down suction

(optional)

|

|

Router type

|

Suction up (right rotation)

Suction down (left rotation)

|

|

Ion wind gun

|

Ion balance pressure≦ ± 15V

Comply with ESD 12M09 158A58

|

|

PCB support method

|

Universal top film

|

|

XYZ drive mode

|

Ac servo

|

|

Vacuum cleaner air volume

|

28-35cm³/min

|

5.Equipment

|

Equipment power

|

Ac:220V± 10% 50/60HZ 3.5KW

|

|

Vacuum cleaner power

|

Ac:380V± 10% 50/60HZ 3kw

|

|

Gas source

|

4-6kg/cm²

|

- 6 -

|

Working environment

|

-20℃ - +45℃

|

|

Working environment humidity

|

30%-60%

|

|

Machine size

|

2014*1230*1650mm

|

|

Vacuum cleaner size

|

640*785*1760mm

|

Weight of machine with vacuum

cleaner

|

1000kg

|

- 7 -

Product Features:

.On-line automatic board depaneling, automatic board feeding,

cutting board out greatly improving efficiency and saving labor

costs

.The whole series are equipped with CCD camera alignment system

to improve cutting accuracy and efficiency and prevent

misoperation

.Imported high-speed spindle is used to cut and separate the board,

which greatly reduces the cutting stress, has small inertia and

quick response

.Double platform structure design, improve cutting efficiency

Automatic tool change:

- 8 -

.Save time and automate

.Reduce human factors

.High precision and strong stability

Structural features:

.X Y Z adopts gantry structure to improve cutting accuracy and

speed

.With automatic cutting function, extend the life of the

milling cutter and reduce the cost

.The waste frame is designed inside the equipment, with a simple

appearance, reducing the footprint

Inboard structure:

.The board is transported by rail

.Plywood positioning function after PCB board feeding

.The feeding structure vacuum suction cup automatically sucks the

PCB to the fixture board for cutting

- 9 -

Outboard structure:

.The finished product and waste are cut on the vacuum suction jig

and placed on the waste and conveyor belt respectively

- 10 -

PCBA pick and place structure:

.Pick and place device: automatic loading and unloading (modular

vacuum suction claw, vacuum device, can be independently

controlled)

.Transmission structure: X movement and Z1 Z2 suction, AC servo

motor control

.Pick-up speed:500mm/sec

- 11 -