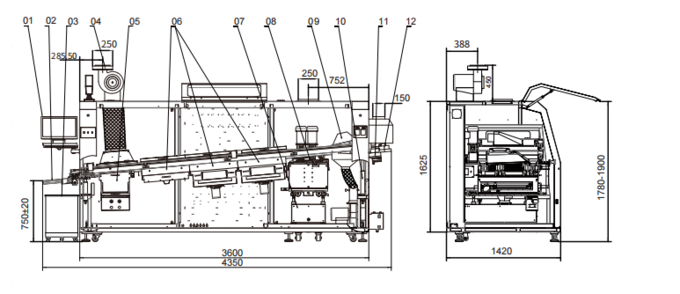

12 Conveyor system

Model No.

YSL-E

YSL-450E

YSL-610E

Dimension: L*W*H(mm)

4350*1420*1750

4350*1520*1750

4350*1690*1750

Weight

Approx.1600kg

Approx.1750kg

Approx.1950k

Power Supply

3PH 380V 50HZ

3PH 380V 50HZ

3PH 380V 50HZ

Start up Power

33KW

33KW

45KW

Normal Running Power

Approx.8KW

Approx.8.5KW

Approx.11KW

Control System

PC+PLC

Spraying movement

Step motor

Spraying Pressure

0.2Mpa~0.4Mpa

Flux Flow Control

Option

Auto Flux Filling

Standard

Exhausting

Top exhaust

Exhausting Pipe Diameter(mm)

Φ250

Exhaust fan power

750W

Preheating Mode

Hot air convection/IR

Temperature Control Mode

PID

Preheating Zone Quantity

3

Preheating Zone Length(mm)

1800

Preheating Temperature Range

Room temperature~200℃

Warm-up Time(min)

Approx.12min(setting: 150℃)

Preheating Blower Motor

150W 3PH 220 VAC

Width(mm)

50~350

50~450

50~610

PCB Conveying Direction

L→R( Option:R→L)

Conveying Speed(mm/min)

500~1800

Conveying Height(mm)

750±20

Available Component Height(mm)

Top120 Option:240 Bottom15

Conveying Speed Control Mode

Closed loop stepless speed regulation by inverter

Finger

Spring Pressing Finger;D-40 Type Finger;Double-hook Finger;Heavy type double hook finger(Options)

Heavy type double hook finge

Option:Special jig for fixture

Conveying Angle

4~7°

Solder Pot Type

Mechanical

Solder Pot Material

Casting Iron

Wave Height Adjustment

Inverter: Digital Control by PC

Cooling type

Air Cooling Option: Water cooling

Solder Pot Heating Power

13.5KW

18KW

Max Solder Pot Temperature

300℃

Solder Pot Capacity

Approx.480kg

Approx.550kg

Approx.640kg

Wave Driving Power

180W*2 3PH 220 VAC

Solder Pot Warm-up Time

Approx.150min(setting: 250℃)

Temperature Control Mode

PID

Finger Cleaning System

Brush